Characteristics of PTFE Teflon Tube and Teflon Tube

Polytetrafluroethylene or PTFE Teflon Tube is a high molecular polymer. It is used in abundance in cable and tubing industry chiefly because of its electrical properties. Also, due to chemical inertness, and high-temperature resistance.

Therefore, the use of this material is on the rise especially in the manufacturing and industrial sectors mainly because of the specific properties of the particular polymer.

Characteristics of PTFE Teflon Tube

Hydrophobic quality – It is hydrophobic in nature. This suggests that the PTFE Teflon Tube is averse to getting wet. It is generally used in such areas where the liquid is transferred from one point to another.

Non-reactive – It is also highly non-reactive in nature. So, even if it comes into contact with other corrosive or reactive metals it does not react. Thus, stops the formation of some other kind of compound. So, it can be used with an extensive range of materials.

Resistant to extreme temperatures – Another very significant feature of this tube is its resistant to high temperatures. It is resistant to extremely cold temperatures. It does not get deformed. Thus, it retains its original texture and shape.

Approved by the FDA – PTFE tubing can also be used in the food and beverage industry. This is due to its non-reactive property even in extreme temperatures. However, it does not change the taste or flavor of the food products which makes it highly sought after.

Properties of Teflon Tubing

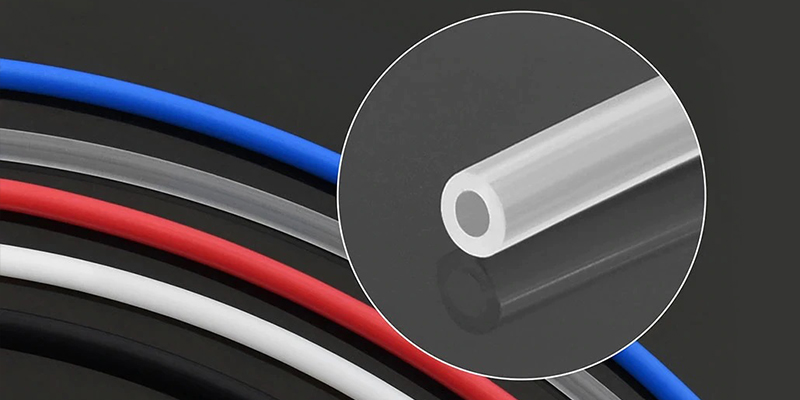

The outer and inner diameters of the tube are of extreme importance. The tube will be utilized well in an assembly. This is where the fittings have been designed to accommodate. Although minor variations in dimension may be accommodated. A tube with a required OD of 6mm may sometimes measure at 6mm. While at other times, it may measure to 6.2mm despite all other parameters remaining unchanged.

Concentricity and tensile strength are some of the properties derived from how the tube is processed during extrusion by Teflon Tube Manufacturers. Factors such as blending, extrusion pressure, etc. result in tensile strength acceptable by global standards. Also, extrusion speed, alignment and the blending process all play a significant part in ensuring high concentricity.

High quality PTFE tube will have a smooth even surface. This means without any pitting, waviness or discoloration.

Factors such as the quantity of extrusion aid, extrusion speed and pressure, all weigh in on how the tube appears. Visual factors such as pitting, waviness and discoloration will definitely highlight the fundamental properties such as tensile strength, elongation and dielectric strength.

It is crucial to note that the above characteristics cover up the essential aspects of PTFE tubing. Products such as anti-static tubing, PTFE tubing and convoluted tubing will each bring a new set of challenges. However, these products are essential for a variety of industries.

To avail of such products, you may get in touch with popular Teflon Tube Manufacturers.