What is a PFA Tube?

PFA, also known as perfluoro alkoxy, is part of the fluoropolymer family. PFA merges the advantages of other fluoropolymers, including FEP (Fluorinated Ethylene Propylene) and PTFE (Polytetrafluoroethylene). This allows PFA to embody the best attributes of both FEP and PTFE tubes.

Durability and Chemical Resistance

PFA tubing is a high-performance tubing that offers superior durability, especially under severe chemical and mechanical conditions. It has best-in-class electrical and mechanical properties and is resistant to most chemicals, solvents, and acids

PFA tubing is considered high-purity tubing and this makes PFA tubing the best choice for gas and semiconductor applications.

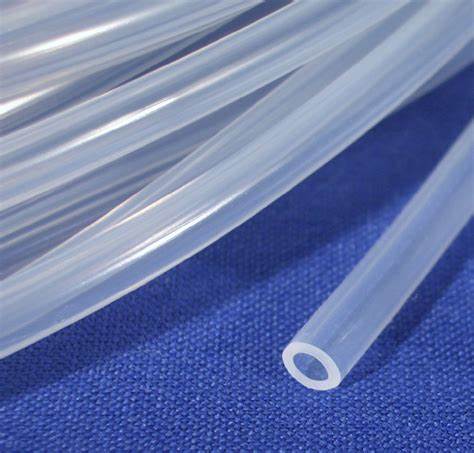

One of the main features of PFA tubing is its transparency. Unlike other types of tubing, PFA tubing is highly translucent or transparent. Due to this material property, visual monitoring of the flow is possible. Visual monitoring is a key requirement of critical applications.

PFA tubing is available in many metric & inch sizes, to suit many applications.

PFA has a melting point of approximately 300-310°C2. This high melting point and its excellent chemical resistance and electrical properties make PFA a preferred choice for demanding chemical, thermal, and mechanical stress environments.

Here are some properties and their value about PFA:

Density:

PFA has a density of approximately 2.12 to 2.17 gm/cu.cm2.

Tensile Strength:

The tensile strength of PFA at 23°C is about 1740 psi or 12 MPa2.

Thermal Conductivity:

PFA has a thermal conductivity of 1.45 Btu·in/h·ft2·°F or 0.209 W/m·K2.

Electrical Properties:

PFA has outstanding electrical properties including high dielectric strength, a low dissipation factor, and a low dielectric constant4.

Chemical Resistance:

PFA is inert to strong mineral acids, inorganic bases, inorganic oxidizing agents, salt solutions, organic acids, anhydrides, aromatics, alcohols, aldehydes, ketones, ethers, esters, chlorocarbons, fluorocarbons, and mixtures of the above compounds

The choice of tubing material depends on the exact requirements of the application temperature range, chemical resistance, bend radius, pressure rating & other mechanical properties.

+91 7028773123

contact@aftubes.com